Electric Roller Belt Conveyor online

Get Latest Price| Payment Type: | T/T |

| Min. Order: | 1 Set/Sets |

| Port: | Shagnhai |

| Payment Type: | T/T |

| Min. Order: | 1 Set/Sets |

| Port: | Shagnhai |

Material: Carbon Steel

Structure: Conveyor System

Condition: New

Warranty: 1 Year

Power: 0.4kw - 22kw

Application: Industry

After Warranty Service: Video Technical Support, Online Support

Material Feature: Fire Resistant

Color: Customers' Request

After-sales Service Provided: Video Technical Support, Engineers Available To Service Machinery Overseas

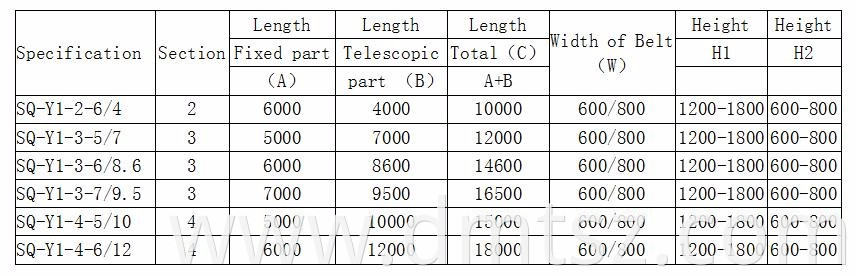

Dimension(L*W*H): Customized Size

Usage: Material Transport

Product Name : Telescopic Belt Conveyor

Showroom Location: India

Brand Name: Pairs Kee

Frame Material: Steel

Belt Material: Pvc/Pvk

Applicable Industries: Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Beverage Shops, Advertising Company

Local Service Location: Pakistan, India, Thailand, Malaysia, South Africa

Feature: Smooth Running

Place Of Origin: Jiangsu, China

Voltage: 380v

Certification: Iso9001:2008/Ce

1.Adjustable:you can adjust buttons according to your own requirements to control the length of the conveyor. If the machine is equipped with a lifting device, you can also control its end height at any time. It can finish loading and unloading by pulling the goods just beside operating personnel. You can load the goods if the belt turning forward and unload goods if the belt turning reversely. Its handling efficiency can reach 30 pieces per minute.

2.Reduce cost: it greatly shortens the distance of carrying materials by labor. It reduces the lay time , labor intensity and the damage to goods so that you can reduce handling cost and improve work efficiency.

3.Flow operation:it can load and unload the goods stably and continuously to avoid messy phenomenon and ground operation all around.

4.Safety operation: It reduces the accidents caused by extensive fatigue of unloading and unloading goods by labor.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.